The landscape of manufacturing is evolving with the introduction of groundbreaking technologies. At the forefront of this evolution are IPG Photonics Corp. and Cobot Systems, who are reshaping the way we approach welding. Their collaboration, enhanced by Universal Robots, is creating new benchmarks in the field. For a deeper dive into this topic, read this insightful article, where Brian Knopp from Cobot Systems discusses these advancements in an interview with TechGen Media.

A Fresh Approach to Welding

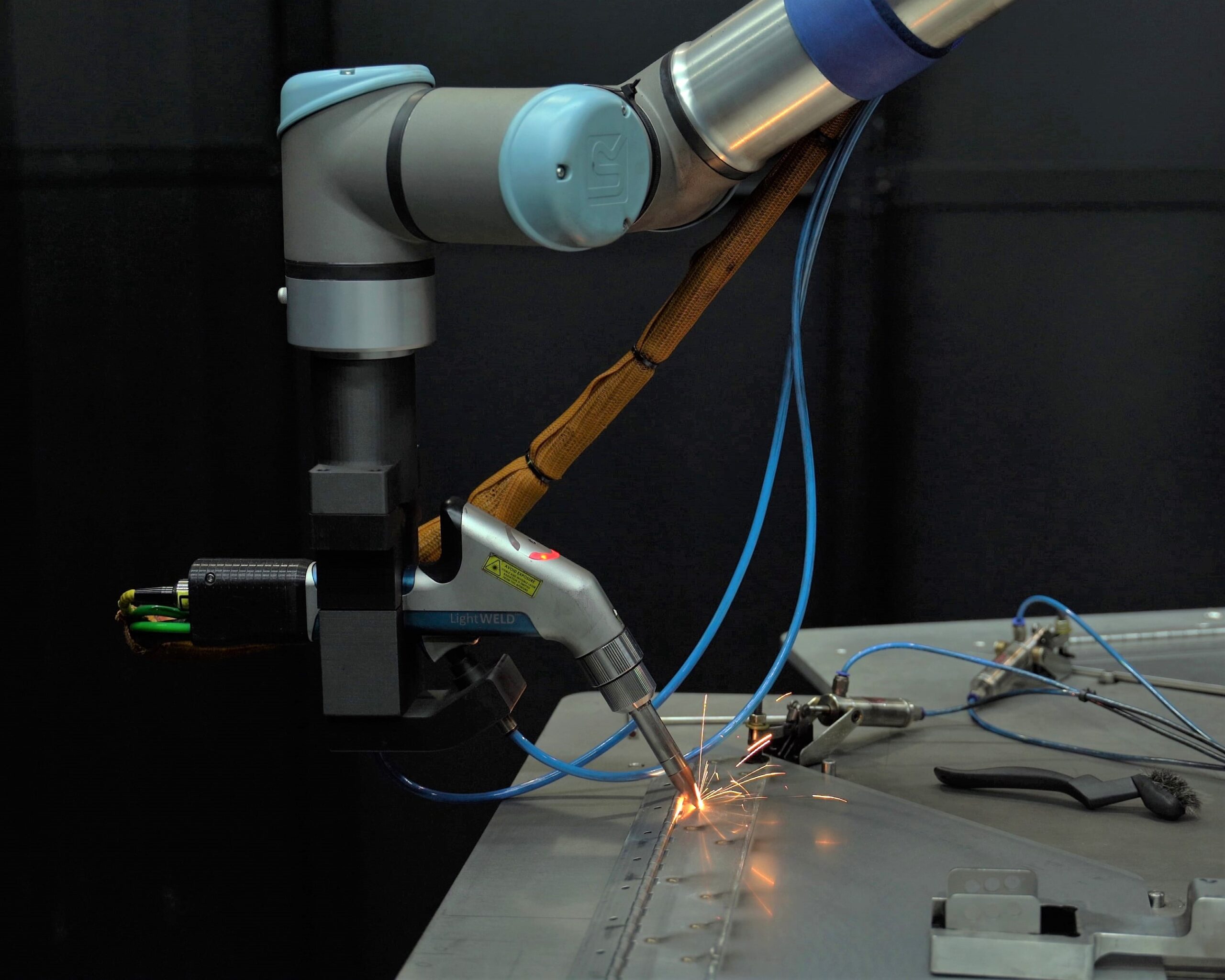

IPG’s LightWELD introduces a new dimension to welding with its handheld fiber laser technology. This tool not only speeds up the welding process by up to four times compared to traditional methods but also offers unmatched precision. Its focused laser beam reduces unnecessary heat and subsequent finishing work, addressing the industry’s need for skilled welding solutions.

The Role of Collaborative Robotics

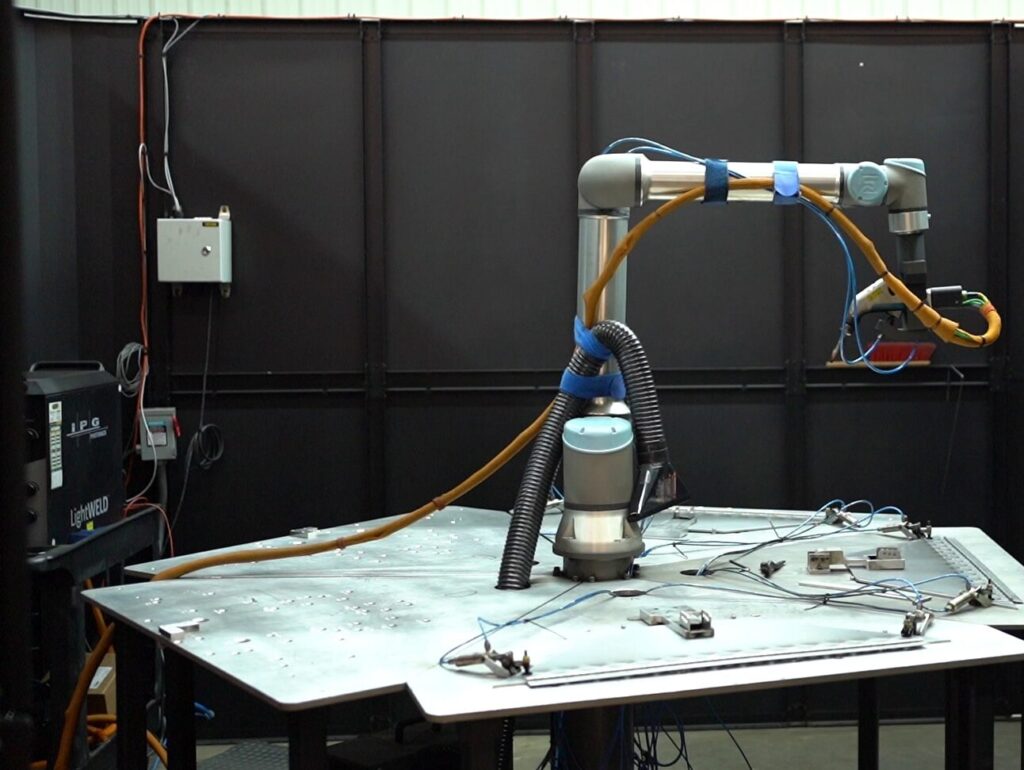

The integration of Universal Robots’ cobots with LightWELD elevates the technology’s potential. Brian Knopp, the brain behind Cobot Systems, envisioned a welding solution that harnesses the efficiency of LightWELD along with the precision and consistency of UR’s cobots.

This synergy enhances weld quality and accelerates production, making it an ideal solution for a broad spectrum of manufacturing applications.

Benefits for Contemporary Manufacturers

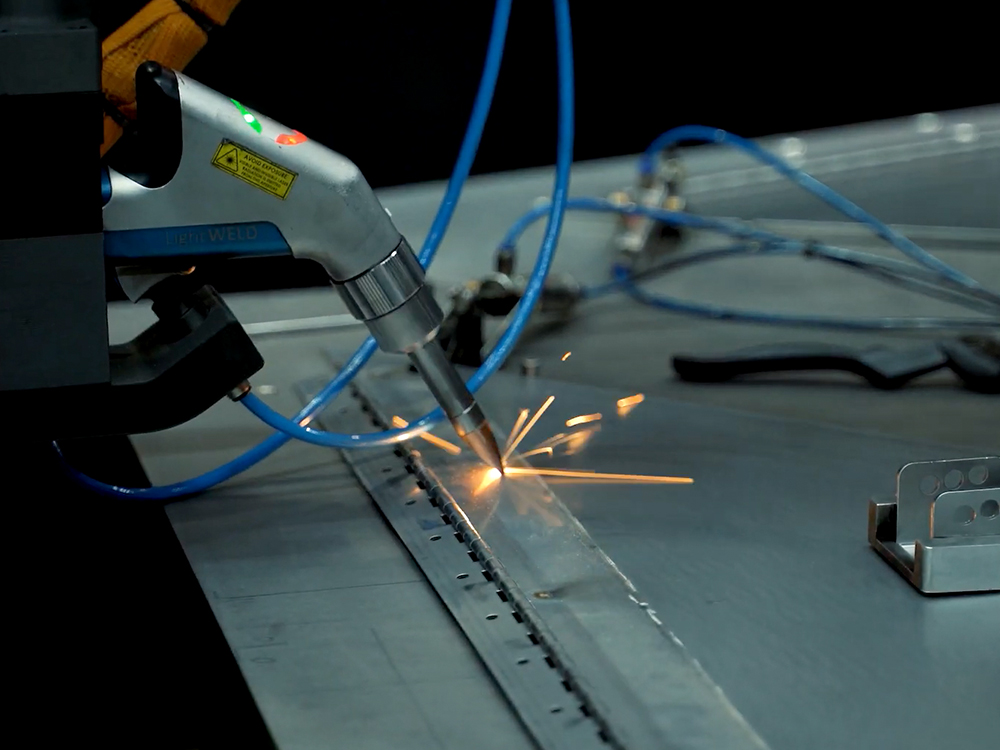

This technology is particularly advantageous for those involved in TIG welding, especially with thin stainless steel. The cobot-guided laser welding system offers unparalleled precision and control, making it a valuable asset for any fabricator. Its versatility in handling different metals and thicknesses, coupled with its energy efficiency, makes it a must-have in modern manufacturing setups.

Prioritizing Safety and User-Friendliness

When it comes to high-powered laser systems, safety is paramount. The LightWELD system incorporates essential safety features, including a contact safety circuit and a two-step laser operation trigger. The integration of safety interlocks and the creation of a light-tight, laser-controlled area ensure operator safety. Despite its advanced capabilities, the system is surprisingly user-friendly, requiring only a few hours of training.

The collaboration between IPG Photonics, Cobot Systems, and Universal Robots signifies more than just technological progress; it represents a practical and innovative response to the challenges in modern manufacturing. This combination of handheld laser welding and robotic automation is not only refining welding processes but also driving the industry towards a more efficient, safe, and flexible future.

For more insights and detailed discussions, check out the full article featuring Brian Knopp’s interview with TechGen Media here.