Perfect parts on time

Quick turnaround

Exceptional customer service

Commitment to quality

Precision Welding and Fabrication Services

Welding and fabrication, the backbone of modern manufacturing and construction, are critical in industries demanding precision-crafted parts.

Our expert team is committed to guiding you towards the most efficient and cost-effective welding and fabrication methods. This approach not only leads to considerable cost savings but also boosts your profits.

You’re more than just a client. We focus on building strong partnerships by assigning you a dedicated Customer Care Specialist for each project. They ensure you’re always informed about the progress of your parts, reducing potential disruptions and ensuring peace of mind throughout the process.

At Cutting Edge Machining and Automation, we revolutionize welding and fabrication by offering a wide range of services that go beyond traditional practices. Our expertise is crucial in sectors where the integrity and performance of components are non-negotiable.

More Than Just a Weld Shop

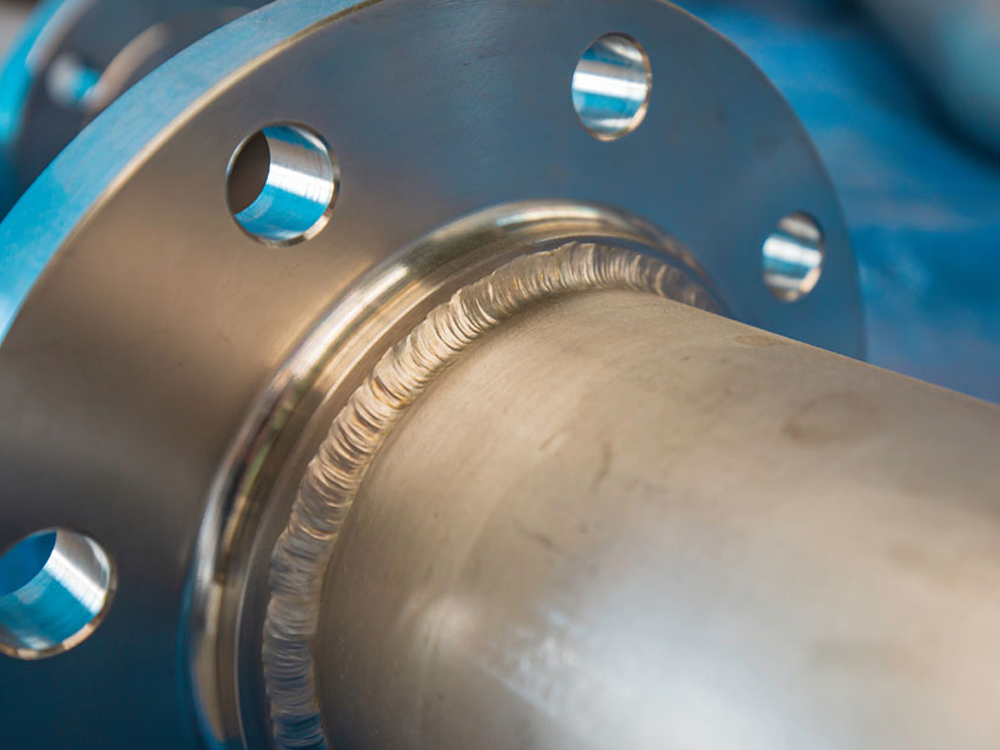

At the heart of our operations lies our expertise in welding and fabrication. Our capabilities extend from standard methods to more advanced and specialized custom welding and fabrication techniques.

Material Capabilities

- Knowledge of Alloys: Understanding different grades of metals is essential for choosing the right type for specific applications.

- Steel alloys, with their vast range of properties from high strength to ductility, are fundamental in various applications. Our expertise in welding these alloys ensures optimal performance and durability in the final product.

- Stainless steel is prone to warping and distortion due to its thermal conductivity and expansion rate. Skilled welders must control heat input and use appropriate welding techniques.

- Aluminum‘s high thermal conductivity and lower melting point demand precise control over welding temperature to avoid burn-through.

Our Welding Methods

- MIG welding is our go-to for robust, efficient welds on a variety of metals and thicknesses. It’s ideal for projects requiring fast production times without sacrificing strength, making it perfect for general fabrication.

- TIG welding is chosen for its precision and versatility, especially in welding thin materials or intricate designs. This method is preferred for high-quality finishes where appearance is as important as durability.

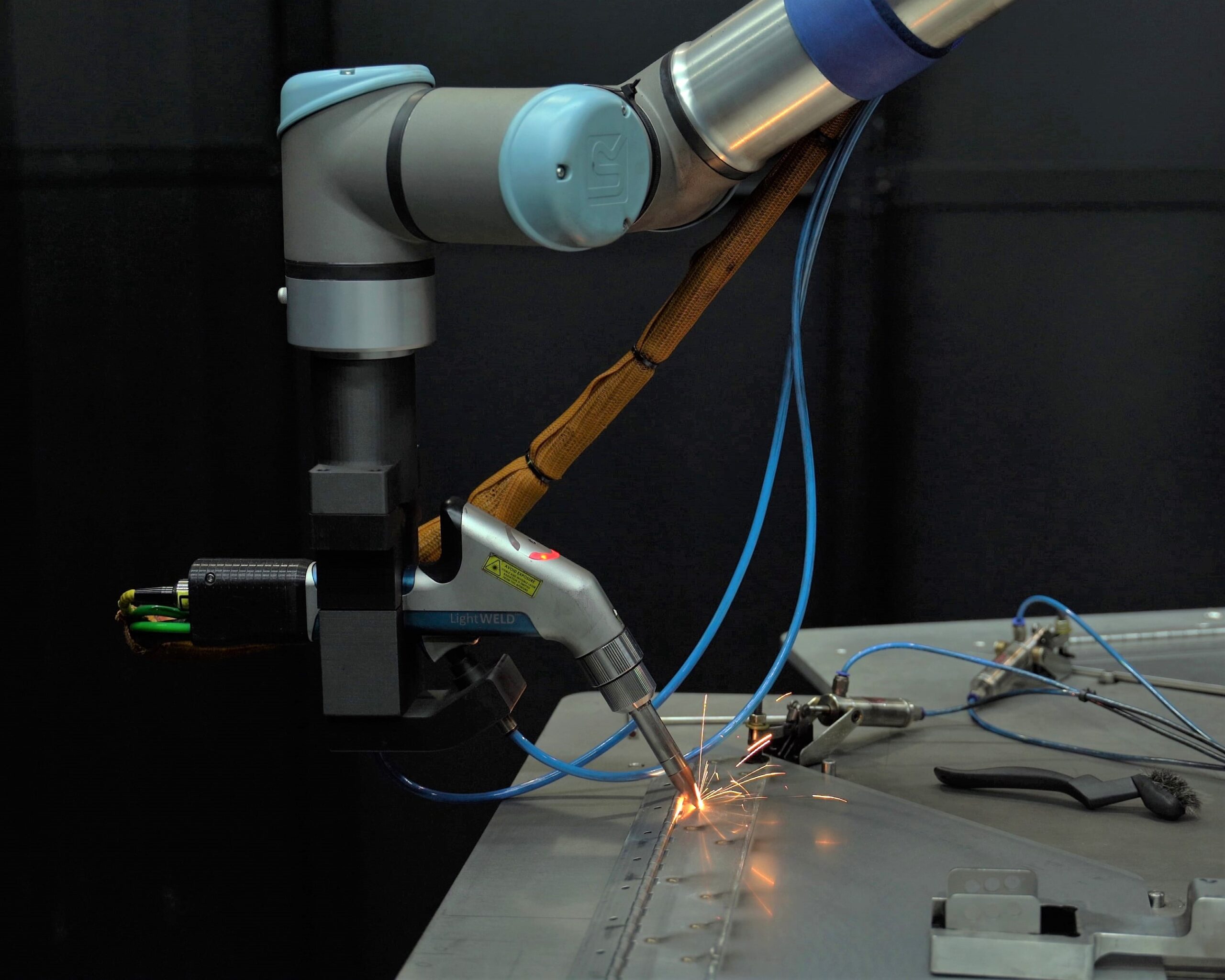

- Laser welding offers unmatched accuracy and speed, suitable for delicate or complex assemblies where minimal heat input and distortion are critical. This advanced technique is excellent for precision components in industries requiring exacting standards, like aerospace and medical devices.

Advanced Facilities and Capabilities

Our weld shop is not just a facility; it’s a hub of innovation and precision. Equipped with cutting-edge robotic technology, we can take on projects of various scales and complexities. This allows us to cater to a wide range of industry needs, from small, intricate parts to large structures.

What is Welding and Fabrication?

Welding and fabrication go hand-in-hand, especially in creating complex structures and machinery.

While welding focuses on joining materials, fabrication is about shaping and assembling components into a final product. Both require a high degree of skill and precision, as the quality of the final product depends significantly on the accuracy of each process.

Advanced technologies and techniques in both fields continually evolve, allowing for more efficient, durable, and innovative applications in various industries.

Why Choose Us for Your

Welding and Fabrication Needs?

In today’s competitive industry, finding a reliable partner for custom welding and fabrication can be challenging. Many businesses struggle with late deliveries, lack of responsiveness, and subpar quality, which can lead to costly downtime and maintenance.

Imagine the impact on your bottom line when deliveries are delayed or when the parts aren’t up to standard. These issues can cause project delays, incur extra costs, and potentially damage your reputation with your customers.

At Cutting Edge Machining and Automation, we deliver perfect parts on time, every single time. Our commitment to quality, coupled with our exceptional customer service, ensures you have a seamless experience from concept to reality. Trust us with your welding and fabrication needs, and we promise to exceed your expectations.

Frequently Asked Questions

What materials are typically used in welding and fabrication?

Welding and fabrication commonly involve metals like steel, stainless steel, aluminum, and alloys. The choice of material depends on the industry and the project’s requirements, such as strength, durability, and corrosion resistance. Should you need it, our team will help you choose the best material for your needs.

Can welding and fabrication be customized for specific project needs?

Yes, welding and fabrication can be highly customized. Techniques and processes can be adapted to meet the specific requirements of a project, whether it’s for a unique design, specific strength needs, or particular material properties.

How do I know if a company will suit my fabrication needs?

A fabricator’s history with projects comparable to yours is a good indicator of their capability to deliver the expected results. Have a look at our past projects at the top of this page, and do not hesitate to reach out so we can evaluate your welding and fabrication needs.

How can I tell if the welding and fabrication provided is high quality?

Ask the fabricator how they ensure the quality of their workmanship. Check if they have any quality control processes in place, how frequently they evaluate their work, and if they offer any guarantees on their products.

Ready to experience the difference? Request a consultation today, and let us show you how our expertise can transform your production process. Simply fill out the form below, and our experienced team will contact you to discuss your specific needs.