Perfect parts on time

Quick turnaround

Exceptional customer service

Commitment to quality

Laser Welding Services

Laser welding has transformed an industry that relies on precision parts, offering high accuracy, efficiency, and versatility. This process is becoming a must in aerospace, medical, automotive, and industrial applications.

We value strong partnerships and building working relationships. To ensure you’re informed about your project’s progress, we provide a Customer Care Specialist for each laser welding project so you always know what’s happening.

Our team focuses on finding the most efficient and cost-effective ways to handle your fabrication needs, which leads to increased savings and higher profits for you.

We quickly respond to quote requests and are flexible with production schedules to meet your deadlines, ensuring you always get your welded components on time.

Capabilities and Advantages of Laser Welding

Laser welding offers several advantages over traditional welding methods, making it a preferred choice for various applications.

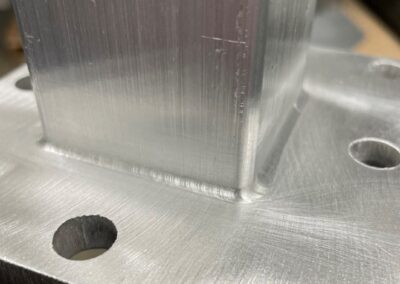

Enhanced precision and accuracy

Laser welding is known for its exceptional precision, ideal for welding small parts without causing damage or excessive thermal distortion.

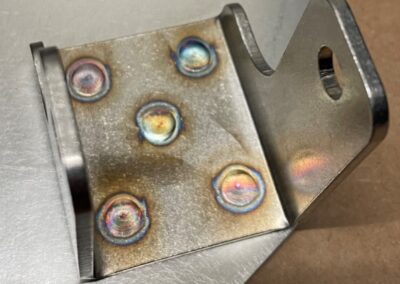

Consistent weld quality

This technology ensures consistent and repeatable welds, enhancing manufacturing efficiency by lowering the rate of defective products.

Reduced distortion risks

Using minimal heat, laser welding significantly reduces the chances of thermal and mechanical distortion in the welded parts.

Increased welding speed

Laser welding is up to 4X faster than traditional methods, leading to higher production throughput.

Versatile welding capabilities

Laser welding is adaptable to various welding configurations, including autogenous and non-autogenous joints, and can handle materials of different thicknesses. It’s also effective for welding galvanized metal, magnetized material and materials that are not the same.

Applications in various industries

Our laser welding services cater to a broad spectrum of industries, each with unique requirements. From aerospace components to medical devices, we ensure that our laser welding solutions meet the highest standards of quality and precision.

Laser Welding Specifications and Equipment

Our facility is equipped with the best laser welding systems from IPG Photonics, allowing us to accommodate a broad spectrum of welding applications.

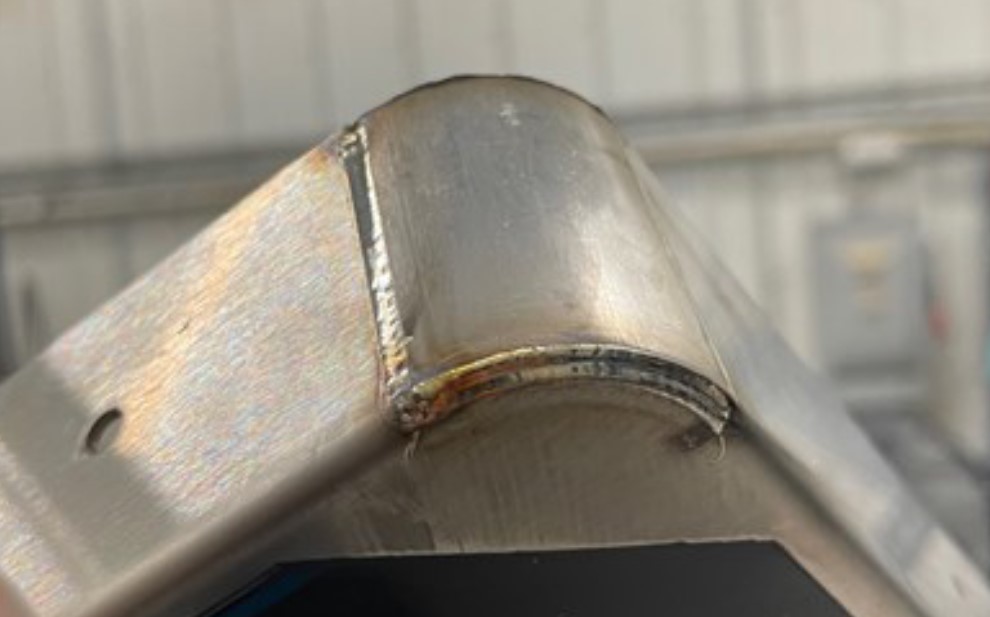

From spot welding, full path welding, fillet welds, with or without filler material, our team has done them all.

Laser welding is a highly specialized process used in various critical applications and is known for its precision and quality. Here are some common applications.

Metal tubing: Laser welding is ideal for joining metal tubing in applications requiring precision and strength, including plumbing, hydraulic systems, and industrial machinery.

Fuel rails: In the automotive industry, laser welding is used for manufacturing fuel rails. The high precision of laser welding is essential for ensuring the integrity and safety of these components, which play a crucial role in the fuel delivery systems of vehicles.

Heat exchangers: For heat exchangers, which are used in many industries for temperature regulation, laser welding provides airtight and secure joints, crucial for efficient thermal transfer and preventing leaks.

Medical devices: The medical sector relies heavily on laser welding to fabricate various devices and implants, including surgical tools and implants. The precision and cleanliness of laser welding are essential for meeting the stringent standards of the medical field.

Laser welding is also increasingly used in aerospace for components like turbine blades, in consumer electronics for small-scale, precision joining of components, and in constructing specialized machinery where traditional welding methods might not suffice.

We provide laser welding services for a diverse range of materials, catering to various industry needs. Materials including:

– Titanium

– Stainless steel

– Aluminum

– Copper

– Nickel

– Steel

– Brass

– Carbon steel

– Low alloy steel

– Silver

– Gold

– Platinum

– Molybdenum

Equip Your Shop with Laser Welding

Cobot Systems, a Cutting Edge Machining and Automation division, can equip and train your team to integrate laser welding in your fabrication operations. We distribute IPG’s handheld laser welders and offer automated solutions using a collaborative robot from Universal Robots.

LightWELD – Turnkey Handheld Laser Welding

- Adjustable laser welding power up to 1500 W

- Preset & user-defined modes optimize material-thickness combinations

- Wobble welding controls for 5 mm of additional weld width

- The rear panel provides intuitive connections for power, process gas and external accessory controls

- Cleaning power up to 2500 W peak for greater welding quality and finishing capability

Laser Welding Cobot Systems

- Universal Robot UR10e cobot

- IPG LightWeld laser welder & utilities dress package

- UR Cap software & safety interface

- Workcell enclosure & access doors

- Work table & modular workholding fixtures & clamps

What is Laser Welding?

Laser welding is an advanced technique that uses a laser beam for high-speed, precise welding of materials, typically metals or thermoplastics.

It’s particularly effective for thin materials and small components and doesn’t need a vacuum environment, unlike some other welding methods.

The technology can weld different materials together and is known for its low heat input, which reduces thermal distortion.

Why Choose Us for Your

Laser Welding Needs?

We are more than just a service provider. Our dedication to excellence shines through in our comprehensive approach to laser welding. Our team specializes in laser welding various materials, including aluminum and steel.

We recognize the uniqueness of each project and offer customized solutions tailored to your specific needs. When you choose Cutting Edge Machining and Automation, you opt for a partner dedicated to delivering precise parts on time, with unwavering quality and value.

Frequently Asked Questions

What types of laser welding processes are there?

There are several laser welding processes, each suitable for different applications. These include, just to name a few:

- Fiber laser welding offers precision, control, speed, and minimal distortion of the welded materials.

- CO2 laser welding is known for its deep penetration capability.

- Pulsed laser welding uses laser pulses for precise control, especially for delicate materials.

- Laser-hybrid welding combines laser welding with traditional arc welding for efficiency and precision.

Cutting Edge Machining Automation offers primarily fiber laser welding and uses IPG Photonics laser welders.

Can laser welding be used for high-volume production?

Yes, laser welding is well-suited for high-volume production. Its high speed and automation capabilities make it ideal for industries where large quantities of precise and consistent welds are required. The efficiency and speed of laser welding can significantly enhance productivity in high-volume settings.

How does laser welding affect the properties of the materials being welded?

Laser welding can have less impact on the material properties compared to traditional welding. Due to its precise heat application and rapid cooling, laser welding minimizes the heat-affected zone, thereby reducing the chance of altering the material’s properties.