Perfect parts on time

Quick turnaround

Exceptional customer service

Commitment to quality

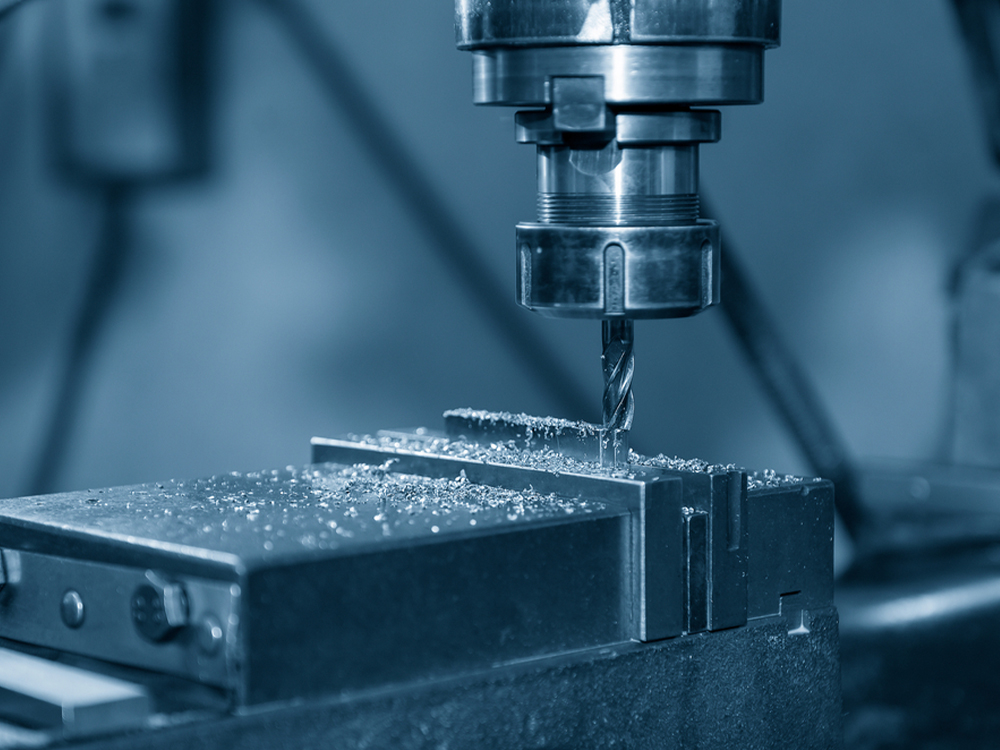

CNC Milling and Turning

Imagine bringing your detailed visions to life with unmatched accuracy – we can help with our CNC milling and turning services.

Our expert team will always advise you on the most efficient and cost-effective manufacturing method, translating into significant cost savings and increased profits for you.

We prioritize partnerships, providing a dedicated Customer Care Specialist for constant updates on your project and parts. This approach fosters transparency, minimizes disruptions, and offers you complete peace of mind.

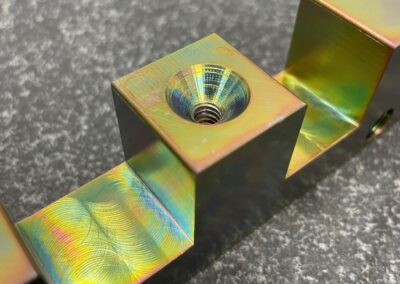

Advanced CNC Technology for Precision Milling and Turning

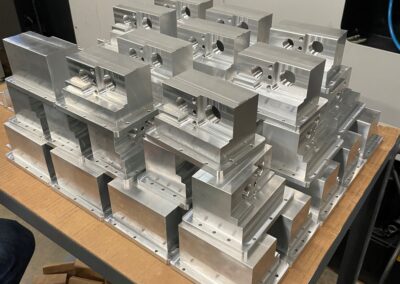

Our full-service precision CNC machining facility leverages the latest high-speed robotic-assisted CNC technology that significantly outshines traditional methods.

This advanced capability enables us to operate “Lights Out 24/7,” ensuring continuous production in machines equipped with spindle speeds of up to 24,000 RPMs. We’re proud to offer advanced CNC milling up to 5-axis and CNC turning up to 7-axis, always offering precision and versatility for your manufacturing needs.

Our expertise lies in specialized CNC production milling and turning, focusing on materials like:

– Aluminum

– Stainless steel

– Kovar

– Copper

– Brass

– Plastics

Our Equipment: Precision and Consistency

We pride ourselves on using state-of-the-art, well-maintained equipment to guarantee precision in every product. Our shop maintains a controlled environment, ideal for machining parts with ultra-tight tolerances, as exact as less than 0.0002 inches.

- Matsurra MX-330 5-Axis Vertical Machining Center

- Mori Seiki NHX4000 High-Precision, High Speed Horizontal Machining Center, 20,000 RPM, Full B Axis

- Mori Seiki NHX4000 High-Precision, High Speed Horizontal Machining Center, 16,000 RPM, Full B Axis

- Seven (7) Brother Speedio S700X1 Drill/Tap CNC Machines with Nikken 4th Axis fully automated running 24-7, 10,000 RPM’s

- Eight (8) Brother Speedio R450 X1, Compact Machining Center, Twin Pallet, 16,000 RPM’s

- Brother TC-32BN QT with Twin Pallets, Twin Nikken 4th Axis Rotary Indexers, 16,000 RPM

- Two (2) Ganesh Cyclone – 32 CS, 7 – Axis Twin Spindle CNC Mill/Turn Center with Full “Y” Axis, bar feed up to 1-1/4″ diameter

- Genturn SL-42Y2 Hybrid Swiss CNC Machine 42 mm bar capacity, 8-Axis, Dual “C” and Dual “Y” Axis, Edge Patriot 551 bar feeder

- Haas VF-3, 5 – Axis CNC Vertical Machining Center 20″ x 40″, 15,000 rpm spindle

- Mori Seiki NL2000SY turning and milling with 4th axis, live tooling, bar feed up to 2-1/2″ diameter

- Three (3) Fanuc RobodrillsT21iLF 24,000 rpm spindle with Fanuc Robotic Loading

- One (1) Fanuc Robodrills T21iEL with Automatic Pallet Changer (Travel x27y16z18) 24,000 rpm spindle

- Genturn 52 CS Y2 CNC Turn Mill Center with Edge Patriot 551 12′ Bar feeder.

- Hardinge Conquest GT CNC Gang Tool Chucker Turning Center

- Hardinge variable speed Bench lathe

- Sakazaki SG-6 universal Cutter Grinder

- Amada 12″ Automatic Cutoff Saw

- Bridgeport Series 1 2HP 9″ x 48″

- Chevalier Grinder 6″ x 18″

- Vibra Bur 150S Burr King Tumbler

- Trinco Sand Blaster

- Jet 6″ Belt & Disc Sander

- Yale Fork Lift 5000 Pound Capacity

- Pneutech RK Series Fixed Speed Compressor – RK-30F-125B

- Pneutech RK Variable Speed Drive Compressor – RK-40VSD-115B

- Zeiss Contura G2 direkt CMM

- Zeiss O-Inspect 322

- Four (4) Mitutoyo Crysta-Apex S544 Coordinate Measuring Machine, Scanning Probe

- OGP Smartscope Flash 302

- Three (3) Luxo Wave LED Magnifier

- ST Industries Optical Comparator with Quadra Check & Surface Illumination

- Lintron Microscope

- Mitutoyo Microscope

- Two (2) Vision Engineering Mantis Microscopes

18″ x 24″ Granite Surface Plate

24″ x 36″ Granite Surface Plate

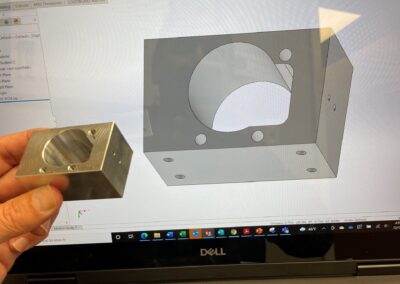

- Seimens NX CAM Part Programming software

- Espirit CAM Part Programming Software

- Solid Edge CAD Software

- Vista 10 by Epicor Shop Management

- Mastercam 5 axis CAM

- CAMPlete simulation software

- Virtual Gibbs 3-D Milling/Solids Package

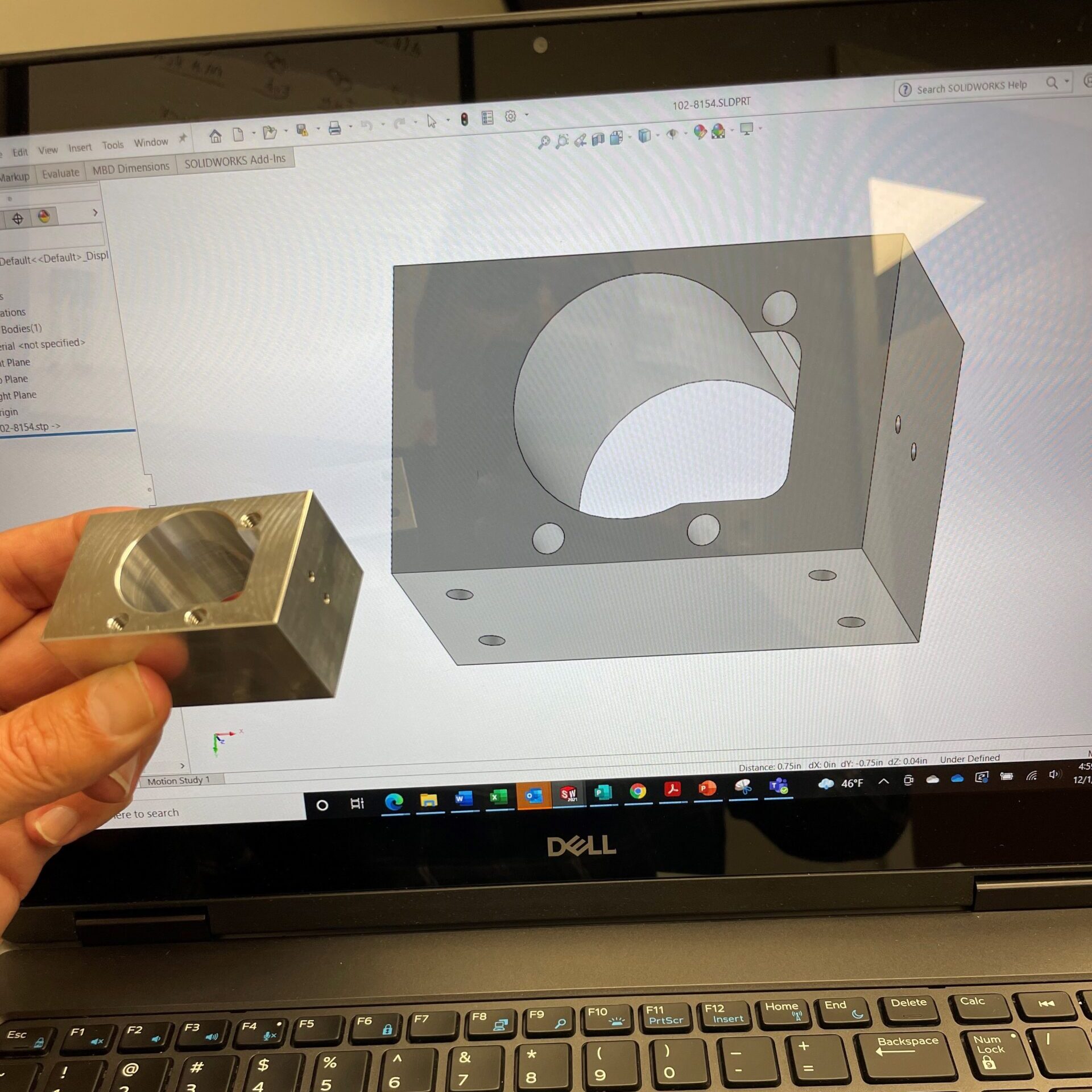

Turning Your Parts Vision into Reality

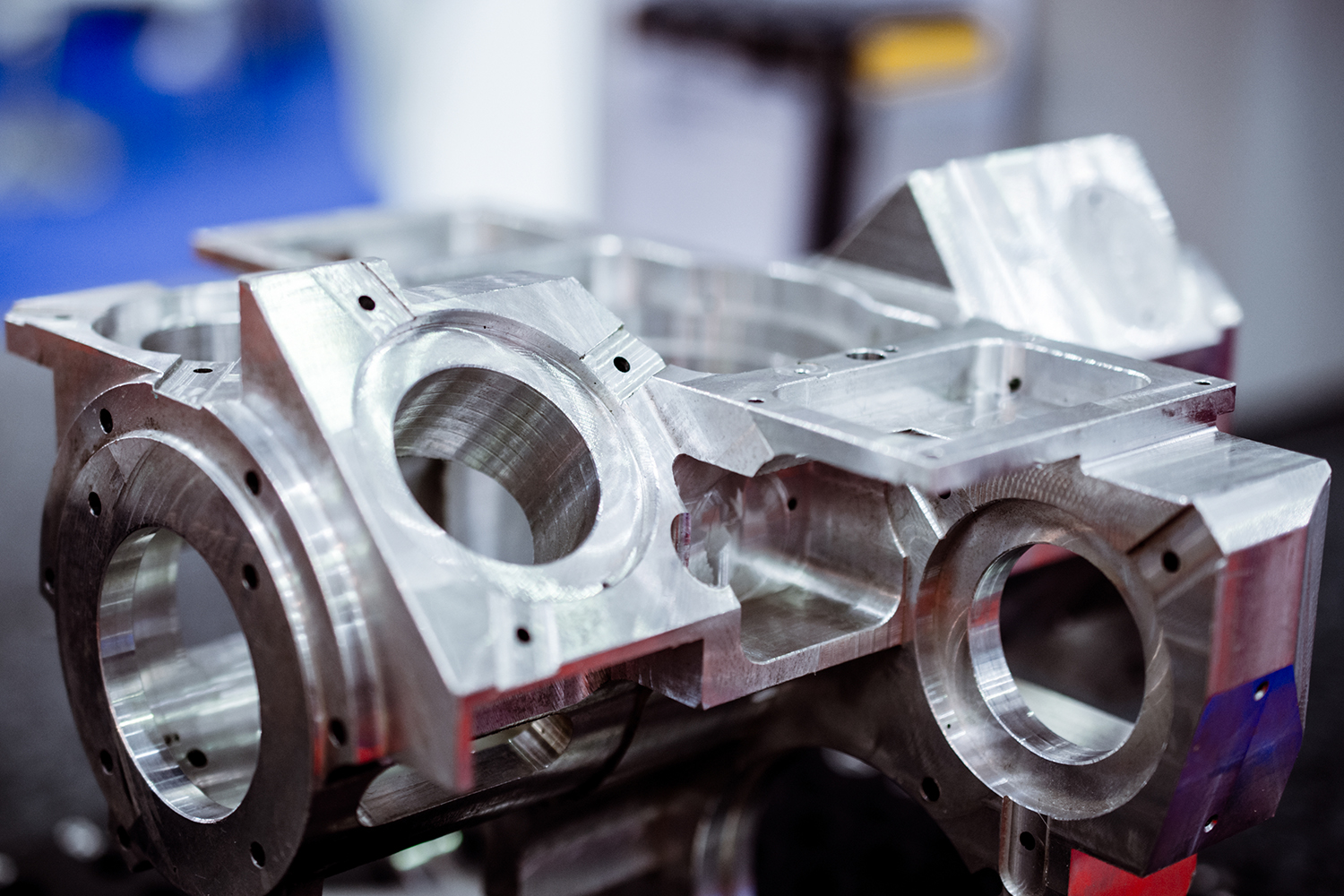

CNC Milling: Versatility in Complex Parts

- Gears: Both straight and spiral gears for mechanical devices.

- Mold tooling: For rapid prototyping, made from materials like steel or aluminum.

- Engine parts: Used in automotive engineering for components like engine blocks.

- Water pumps: Multi-axis mills create impellers for hydraulic equipment.

- Forming punches: Manufacturing equipment for sheet metal fabrication.

- Fittings: Essential for connecting various parts.

- Brackets: Featuring custom threads and holes, more complex than standard sheet metal brackets.

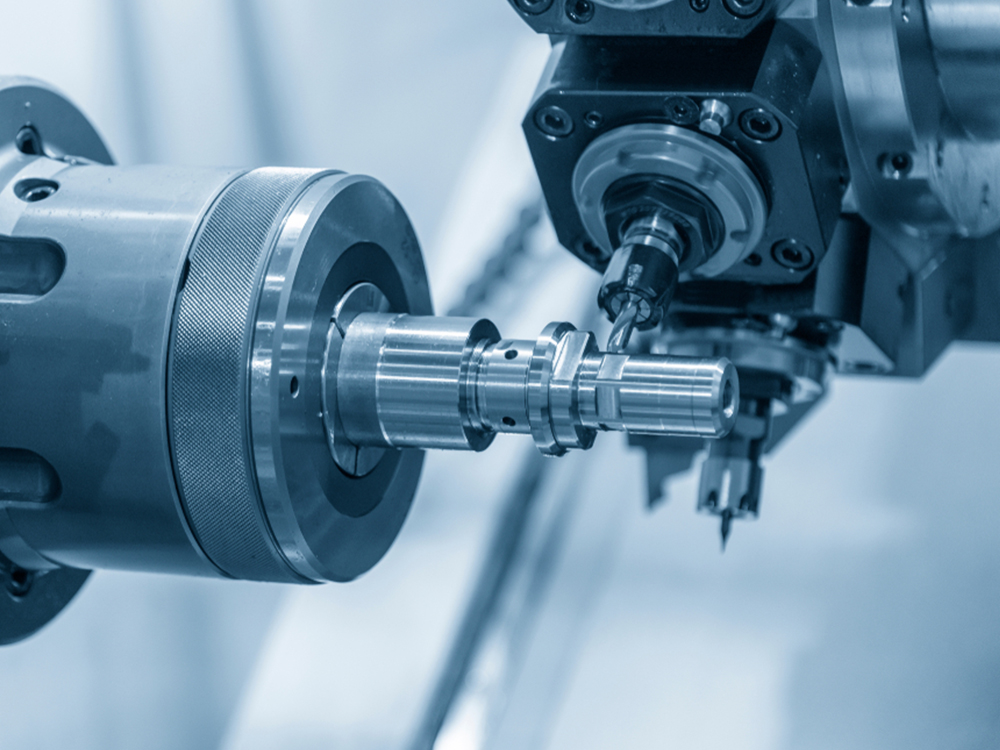

CNC Turning: Precision in Round Profiles

- Rollers: Fabricated with tight tolerances for industrial applications.

- Nuts and bolts: Suited for items requiring high accuracy.

- Turbines: Round turbine blades for the energy industry.

- Shafts: Perfect for creating shafts with rounded profiles.

- Flanges: Used to strengthen beams and pipes.

What is CNC Milling and Turning?

CNC milling and turning are vital in modern manufacturing, each bringing unique benefits.

CNC Milling

CNC milling is a process where computer-controlled machines carve and shape material into diverse and intricate designs. CNC mills are capable of creating various shapes using different cutting tools for operations like roughing and finishing. They’re also effective for post-machining, adding details to turned or 3D-printed parts.

CNC Turning

CNC turning involves rotating a workpiece against a cutting tool, primarily used for shaping cylindrical parts to the required dimensions and specifications.

Combined Strengths

Combining these two processes maximizes their benefits. Typically, CNC turning shapes the part, followed by milling to add asymmetrical details. This blend offers a comprehensive solution, enabling a wider range of shapes and finishes with high precision and quality.

Whether your project demands intricate details or specific aesthetic finishes, our CNC turning services are designed to achieve your exact specifications with utmost precision.

Why Choose Us For Your CNC Milling and Turning Needs?

At Cutting Edge Machining and Automation, we excel in providing advanced CNC machining services, perfectly tailored to meet your specific needs for custom parts and components.

Our approach combines precision with quick turnaround, ensuring your projects are delivered with exceptional accuracy and speed. Thanks to our state-of-the-art equipment, we’re able to ramp up production quickly, meeting your timelines without ever sacrificing quality.

Choosing Cutting Edge Machining and Automation is about choosing a partner who values detail, efficiency, and customer satisfaction as much as you do. We’re committed to delivering CNC-machined parts that meet and exceed your expectations.

Ready to experience the difference? Request a consultation today, and let us show you how our expertise can transform your production process. Simply fill out the form below, and our experienced team will contact you to discuss your specific needs.