Perfect parts on time

Quick turnaround

Exceptional customer service

Commitment to quality

Precision Laser Cutting Services

Cutting Edge Machining and Automation leverages the power of precision laser cutting and delivers superior quality and timely execution of all projects, setting a new standard in manufacturing.

We prioritize partnerships, providing a dedicated Customer Care Specialist for constant updates on your project and parts. This approach fosters transparency, minimizes disruptions, and offers you complete peace of mind. Our expert team will always guide you towards the most efficient and cost-effective fabrication process, translating into significant cost savings and increased profits for you.

Industries we work with include marine, aerospace, automotive, medical devices, electronics, and energy sectors. In each of these fields, the precision and versatility of laser cutting is indispensable.

We’re not just delivering parts; we’re crafting perfection tailored to your needs every single time.

Laser Cut Steel and Aluminum

Specifications & Equipment

Laser Cut Steel

- Types: Stainless steel and mild steel

- Thickness Capability: Up to ¾” thickness

Laser Cut Aluminum

- Series Compatibility: Efficient in cutting 5052 series up to ½” thick and 6061 series up to ⅛” thick

- Outcome: Ensures precise and clean cuts suitable for numerous applications

Size of Parts

- Capability: Able to handle both rough and finished parts

- Maximum Size: Our BySmart 3015 accommodates materials up to a size of 60” x 120”

Materials Processed

- Range: Laser cut metal is our specialty, with a focus on stainless steel, mild steel, and various grades of aluminum.

- Project Scope: We are equipped to address a wide variety of laser cutting projects, ensuring versatility and adaptability for all your needs.

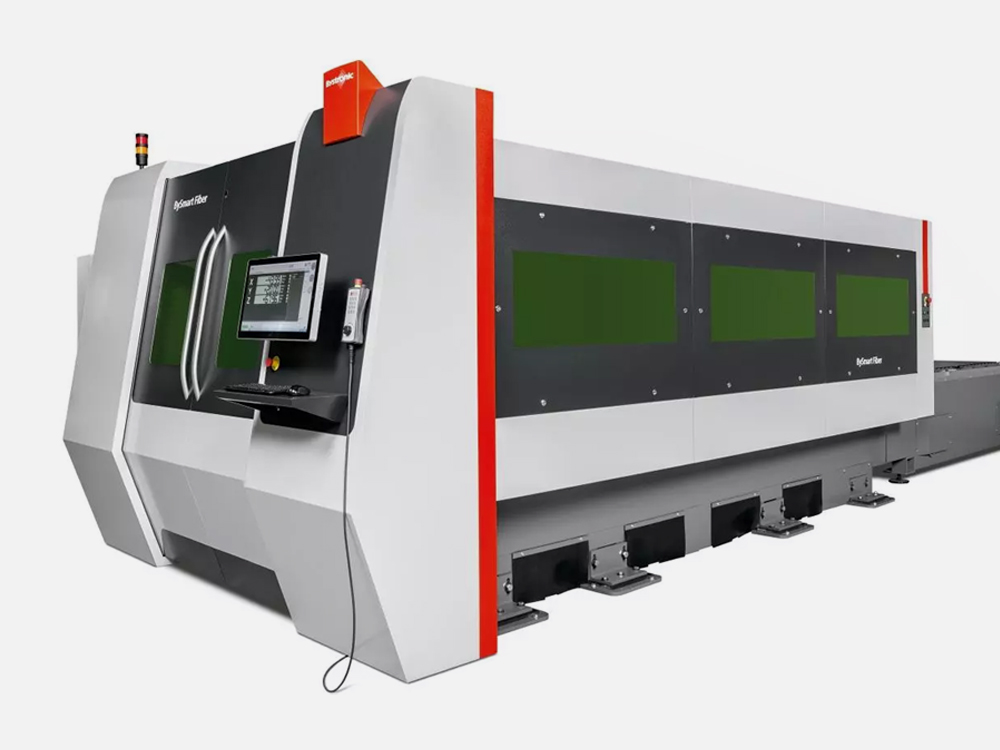

Bystronic BySmart 3015 Laser Cutter

The Bystronic BySmart 3015 Laser Cutter represents the apex of laser cutting technology. This machine is specifically designed for high precision and efficiency in cutting metals like steel, stainless steel, and aluminum.

Key features and capabilities of the Bystronic BySmart 3015 include:

- Cutting Efficiency: Features a high-speed cutting head and advanced fiber wavelength technology, ensuring fast and clean cuts.

- Versatile Cutting Area: Boasts a generous cutting area of 122” (X) x 62” (Y) x 4” (Z), capable of handling large sheets up to 60” x 120”.

- Accuracy: Offers exceptional positioning accuracy (Pa) of ± 0.004 and repeatability (Ps) of ± 0.002, ensuring consistent and accurate cuts.

- Edge Detection: Maintains an edge detection accuracy of ± 0.02, crucial for intricate designs and precise edges.

- Capability with Various Materials: Capable of cutting steel up to .75”, stainless steel and aluminum up to .62”, and brass and copper up to .312”.

Fladder Gyro 200 Deburring Machine

The Fladder Gyro 200 deburring machine is an integral part of the post-laser cutting process. This machine, renowned for its efficiency and precision, is the ideal solution for deburring, edge rounding, achieving superior surface finishes, sanding, and denibbing.

Key features of the Fladder Gyro 200:

- Versatile Functionality: Expertly designed for multiple finishing processes, making it a versatile tool for various post-cutting requirements.

- Innovative Movement: The spindles counter-rotate in pairs, while the entire gear head performs an oscillating and rotating movement. This unique motion ensures a uniform finish across the surface of the workpiece.

- Uniform Finishing: The combination of movements by the gear head and spindles guarantees a consistently high-quality finish on all laser-cut parts.

The Gyro 200’s advanced capabilities ensure that each laser-cut part not only meets but exceeds our rigorous standards for quality and safety. It is pivotal in ensuring that every piece has smooth, burr-free edges, and an impeccable surface finish, reflecting our commitment to delivering excellence in every project.

What is Laser Cutting and How Does It Work?

Laser cutting is an advanced technique that uses a high-powered laser beam to cut or engrave materials like metal, plastic, and composite. The laser, either CO2 or solid-state, generates intense light that heats and vaporizes the material at a specific point.

Controlled by a computer for precision, the process is aided by an assist gas like oxygen or nitrogen, which helps in material removal and ensures a clean cut.

This method is renowned for its accuracy, speed, and ability to produce complex shapes with minimal waste, making it highly efficient and versatile for various applications.

Why Choose Us for Your Laser Cutting Needs?

At Cutting Edge Machining and Automation, excellence is our standard, and precision is our promise. We’re not just delivering parts; we’re crafting perfection tailored to your exact needs every single time.

Our rapid turnaround and unwavering dedication to accuracy set us apart in the laser cutting sector. Whether it’s laser-cut aluminum, steel, or stainless steel, our skilled team executes each job with precision and efficiency.

Choose Cutting Edge Machining and Automation for high-quality laser cutting, exceptional customer service, and on-time delivery.

Frequently Asked Questions

How Thick of Steel Can a Laser Cut?

The thickness of steel that a laser can cut depends on the type of laser cutter and its power. Industrial laser cutters like the Bystronic Bysmart 3015 can cut steel up to ¾” thick.

Can You Laser Cut Stainless Steel?

Yes, laser cutting is highly effective for stainless steel. Advanced laser cutters, like the Bystronic Bysmart 3015, can precisely cut stainless steel. This process is ideal for creating intricate designs and achieving smooth, clean cuts with high accuracy.

Is Laser Cutting Suitable for Aluminum?

Absolutely! The laser cutting aluminum process is renowned for delivering precise, clean cuts, making it an optimal choice for crafting high-quality aluminum parts. Laser cutting is well-suited for grades like 5052 series up to ½ inch thick and 6061 series up to ⅛ inch thick.

How Does Laser Cutting Compare to Traditional Cutting Methods?

Laser cutting offers greater precision, flexibility, and speed compared to traditional cutting methods like machining or waterjet cutting. It allows for intricate designs and minimal material wastage.

Can Laser Cutting Be Used for Detailed and Intricate Designs?

Yes, one of the significant advantages of laser cutting is its ability to produce highly detailed and intricate designs that would be challenging or impossible with traditional cutting methods. This precision makes it ideal for complex parts in industries like manufacturing, aerospace, electronics, and jewelry.

Ready to experience the difference? Request a consultation today, and let us show you how our expertise can transform your production process. Simply fill out the form below, and our experienced team will contact you to discuss your specific needs.