Perfect parts on time

Tolerances as tight as 0.0002″

Machine virtually any material up to 1.5″ in diameter

Exceptional customer service

Swiss Machining Services

Swiss machining is a process renowned for manufacturing intricate components for all projects and needs. Our Swiss machining services use advanced CNC Swiss machines and Swiss lathes to produce your parts perfectly and on time!

Our goal is to build strong partnerships, and we do that by making you and your project our top priority. When you partner with us, we assign you a dedicated Customer Care Specialist. Your CCS will keep you informed about your project and parts to ensure you are receiving the most efficient and cost-effective manufacturing solutions.

Material Capabilities

At Cutting Edge Machining and Automation, we can machine virtually any round or hex bar stock up to 1.5″ in diameter.

Swiss machines are renowned for their versatility in machining various materials, making them indispensable in multiple industries. These materials range from plastics and composites to an extensive selection of metals, each chosen for its unique properties and applications.

Steel: A staple in sectors like automotive, aerospace, and construction. Steel is favored for its robustness and durability.

300 & 400 Stainless Steel: This material is a popular choice in the medical field, food processing and aerospace industries owing to its resistance to corrosion and ease of sterilization.

Titanium: Valued in the aerospace, medical, and military sectors for its exceptional strength-to-weight ratio and biocompatibility, making it suitable for both structural components and medical implants.

Aluminum: Widely used in automotive, aerospace, and construction due to its lightweight and resistance to corrosion. Its malleability also makes it a preferred choice for intricate designs.

Brass: Commonly used to manufacture plumbing fixtures and electrical components, brass is known for its machinability and anti-corrosive properties.

Bronze: Often found in bearings, bushings, and various marine applications, bronze is recognized for its strength and resistance to wear and corrosion.

Inconel, Monel and various other high-temperature materials: A superalloy primarily used in aerospace, nuclear, and chemical industries, Inconel stands out for its ability to retain strength and resist corrosion, even in extreme temperatures and harsh environments.

Others: 17-4 PH, Copper and many copper-based alloys, Magnesium, Nickel and Nickel alloys, Plastics, Tool steels, Various carbon and alloy steels

In addition to these materials, our Swiss CNC machines and lathes can also work with other specialized alloys and composites, each selected for specific properties such as heat resistance, electrical conductivity, or lightweight strength.

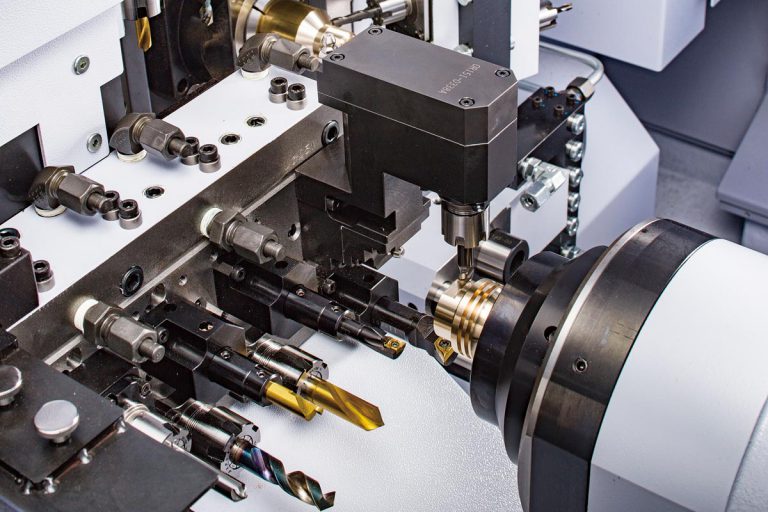

Our Equipment: Precision and Consistency

We pride ourselves on using state-of-the-art, well-maintained equipment to guarantee precision in every product. Our shop maintains a controlled environment, ideal for machining parts with ultra-tight tolerances, as exact as less than 0.0002 inches.

We use a range of high-quality STAR Swiss Style CNC Automatic Lathes, ensuring that every product is accurate and delivered on time. With our advanced machinery, you can trust in the consistent quality and precision of your projects.

– ECAS-20

– SB-20 TYPE E

– SR-20R

– SR-20RII (4)

– SR-20RIII

– SR-32J (2)

– SW-20 (2)

– SR-20JII (3)

– SR-38 TYPE A

– Gray-mills aquatic parts cleaner

– Nova Vibratory tumblers

– OTEC CF Finishing Machine (2)

– Crest F100-1812C Ultrasonic Vapor Degreaser

– Crest 500 HT Ultrasonic Cleaner

– Jenoptik Opticline Contour 203

– Starett HB400 Comparator

– Starett HDV400 Comparator

– Starett Precision Optical HE400 (2)

– Variable Power Binocular Microscopes

– Mitsubishi Md Pro II (BA-8) Wire EDM

– Bridgeport Knee Mill

– Epilog Fusion 32, 50W Fiber Laser

– Barrett Oil Extractor

SR-20JII

Our SR-20JII boasts an extensive tooling capacity with its combination of a 6-tool turning platen, a 5-spindle cross drilling unit, and an 8-spindle back working tool post, enabling a wide array of machining possibilities.

SR-38 Type B

Our SR-38 Type B sliding head lathe, designed for efficient use of space, delivers extensive capabilities and features. It accommodates raw materials up to 42mm in diameter in NGB mode, with the flexibility to switch easily between Swiss type (guide bush mode) and non-guide bush modes. Enhanced metal removal efficiency is achieved through an independent X3 slide that facilitates balanced cutting on the main spindle.

What is Swiss Machining?

Swiss machining, a technique with roots tracing back to the Swiss watchmaking industry, was developed to meet the demand for precise, intricate components. Originally designed to fabricate small, complex watch parts, Swiss machines have become a critical tool in modern manufacturing.

This machining process is characterized by its unique method of holding and feeding the workpiece through a guide bushing. The workpiece’s support near the cutting action minimizes deflection and vibration, allowing for the production of parts with extremely tight tolerances.

Why Choose Us for Your Swiss Machining Projects?

At Cutting Edge Machining and Automation, we pride ourselves on delivering top-tier Swiss machining services. Our team of experienced machinists have the expertise to handle even the most challenging projects, ensuring perfect parts every time.

We also understand the importance of timely delivery in today’s fast-paced industries. That’s why we guarantee quick turnaround times without compromising on quality. Our state-of-the-art equipment and streamlined processes allow us to provide efficient services without sacrificing precision.

Our exceptional project management ensures a smooth, efficient journey from start to finish. With us, you get a reliable, hassle-free experience that guarantees the success of your Swiss machining needs.

Frequently Asked Questions

What is a Swiss lathe used for?

Swiss lathes are designed for machining small, complex parts with a high degree of accuracy. They typically have a diameter capacity of less than 38 mm (1.5 in) and can operate at extremely high speeds, making them well-suited for machining high-precision parts.

What types of parts are typically produced on CNC Swiss machines and lathes?

Swiss CNC machines are renowned for their ability to manufacture small, intricate parts with precise geometries and exacting tolerances. This capability makes them ideal for a range of applications across various industries.

Examples include:

- Medical implants and prosthetic devices

- Aerospace components, including connectors, fittings, and valves components

- Automotive components, including fuel injectors, valves and electrical connectors

- Fittings and connectors used in hydraulic and pneumatic systems

- Custom fasteners such as screws, bolts, and nuts

Can Swiss Machining be used for prototyping?

Swiss machining is highly suitable for prototyping, especially for small, intricate parts requiring high precision and complex geometries.

Cutting Edge Machining and Automation works with partners to offer services from prototyping through full production. This allows you to work with one facility and provider from the beginning avoiding additional learning curves when switching to volume production.

Can Swiss machining be used for large-scale production?

Swiss machining can be used for large-scale production, particularly when manufacturing small, precision parts in high volumes. Its efficiency and precision make it well-suited for repetitive, high-volume production runs. A big benefit of Swiss machines is that most parts come off the machine completed, avoiding costly secondary operations and maximizing production efficiencies.