Practical Automation

Solving Labor

Challenges

Increased Productivity

Exceptional customer service

Custom Robotic Integration Services

We understand the pivotal role robotic integration plays in transforming industries that face labor and productivity challenges.

Upon discussing your project and needs, our team will select components and technologies to design the right robotic solution. From the initial design to full integration and support to production, our team has successfully integrated hundreds of automation cells.

Whether you are exploring traditional automation or collaborative robots, we have the expertise to help you automate your operations.

Cobots and robots have become indispensable in the manufacturing industry due to their versatility and efficiency. These tools are designed to perform a wide range of tasks, each characterized by speed and precision that surpasses manual labor.

Below are some of the key applications we can help with using robotic integration:

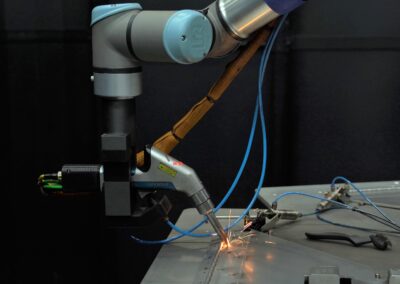

- Welding: Cobots are used for various welding processes, including spot welding and arc welding. They provide consistent quality and speed, significantly reducing the time taken for welding tasks.

- Machine Tending: Cobots automate machine loading and unloading, improving precision and efficiency in the process. They help maintain smooth operations, minimize downtime, and reduce manual labor, leading to lower operational costs.

- Palletizing: Robots streamline the palletizing process with their adaptability to different products and packaging types. They ensure accurate stacking, optimize space utilization, and decrease the reliance on manual labor.

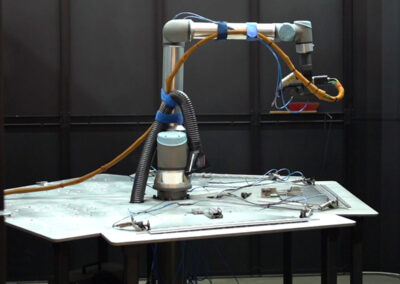

- Polishing, grinding, and buffing: These robotic finishing processes achieve consistent and high-quality surface finishes on products.

- Painting: Robotic painting systems deliver precise and uniform application, essential for achieving high-quality finishes in automotive and other manufacturing industries.

- Packaging & labeling: Automated systems handle the packaging and labeling of products with remarkable efficiency, significantly speeding up this final stage of the manufacturing process.

- Assembly & disassembly: Robots are equipped to handle complex assembly tasks, ensuring precision and reducing the likelihood of errors.

Robotic integration in these areas not only enhances productivity and quality but also contributes to safer working conditions by taking over tasks that could be hazardous for human workers.

Incorporating robotic or cobotic systems into your processes can bring several key advantages:

- Enhanced consistency: Automation ensures uniformity in production, leading to consistent quality in output.

- Quality and yield improvement: Automation minimizes waste and defects, thus enhancing the overall quality of products and increasing yield.

- Greater accuracy and repeatability: Robots offer precise and repeatable operations, which is essential for tasks requiring high levels of accuracy.

- Maximized uptime: Robotic systems reduce downtime in production, contributing to increased overall operational efficiency.

- Boosted productivity and utilization: Robots enhance the productivity of processes and make better use of resources and facilities.

Robotic Brands We Work With

What is Robotic Integration?

Custom robotic integration involves designing and implementing robotic systems tailored to the specific needs and challenges of your business or manufacturing process. This process includes analyzing the unique requirements of the production line, selecting appropriate robotic technology, and customizing the system for optimal performance and efficiency.

Why Choose Us for Your Robotic Integration Needs?

When you choose CEMA, you’re choosing a partnership tailored to your unique needs. Our years of experience in the industry have taught us the value of understanding and exceeding our clients’ expectations. We specialize in creating custom robotic solutions that go beyond the ordinary, ensuring your project significantly improves your operations and boosts productivity.

Our team is committed to delivering innovative and effective solutions for your facility. With CEMA, you’re getting cutting-edge technology and a partner dedicated to enhancing your operations and driving your success.

Frequently Asked Questions

How do you find the right robotic integrator?

When choosing a robotic integrator, it’s important to consider their experience, the technology they use, and the type of supporting or ancillary services they provide. Look for integrators with a proven track record who use industry-leading technology and offer comprehensive services to ensure a smooth integration project.

In which industries can robotic integration be found?

Robotic integration is versatile and can be found in various industries, including automotive, consumer goods, electronics, food and beverages, life sciences, and plastics. Each industry uses robotic solutions to enhance productivity in specific ways.

What does a robotics integrator do?

A robotics integrator assesses current opportunities to increase productivity and efficiency by adding robotic systems. They work with multiple technologies to reliably and simply solve the selected application. They aim to achieve more consistent results, cut labor costs, and improve production efficiency.

What are the benefits of robot integration?

Robotic systems integration offers high flexibility, scalability, and accuracy, providing a significant return on investment. Common industrial uses for robots include machine tending, assembly, painting, dispensing, palletizing, production inspection, material handling, welding, and production testing.

Ready to experience the difference? Request a consultation today, and let us show you how our expertise can transform your production process. Simply fill out the form below, and our experienced team will contact you to discuss your specific needs.