Less Heat Distortion

Ultra-fast Welding Speeds

Complete All-in-One Package

No Robotics Expertise Needed

Increase Your Production Throughput with the Industry-First Laser Welding Cobot System.

- Are you struggling to keep up with demand due to unfilled welder positions?

- Are you turning away work because your team can’t keep up?

- Are you dealing with tight deadlines that keep you up at night?

- Are you struggling to find the right solution to automate your TIG welding operations?

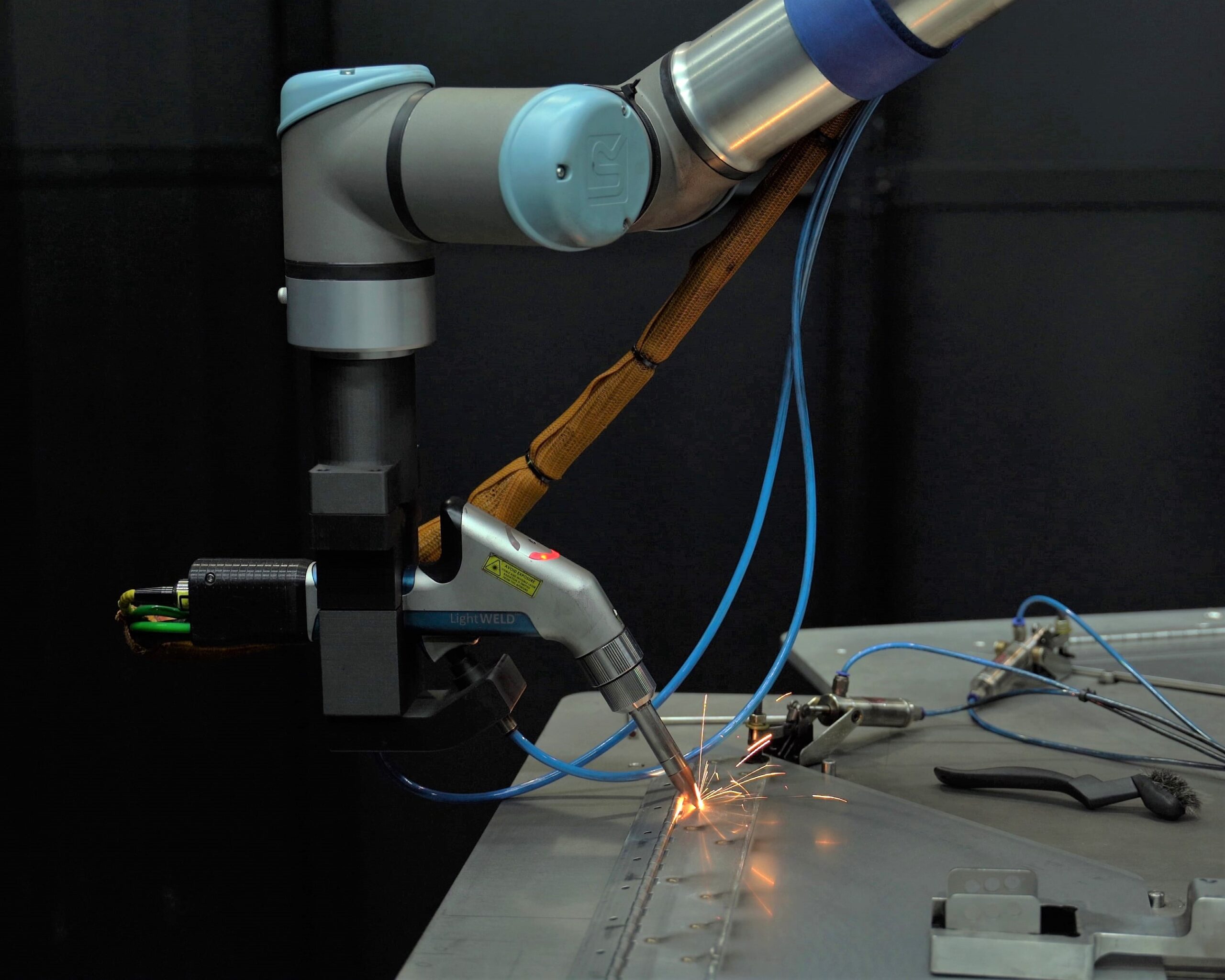

Laser Welding Cobot System

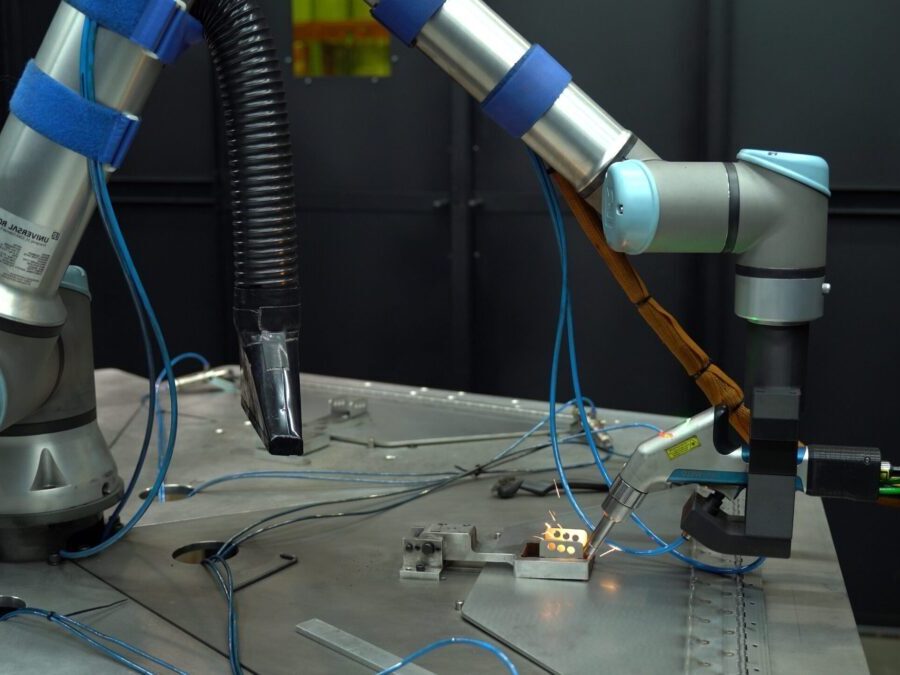

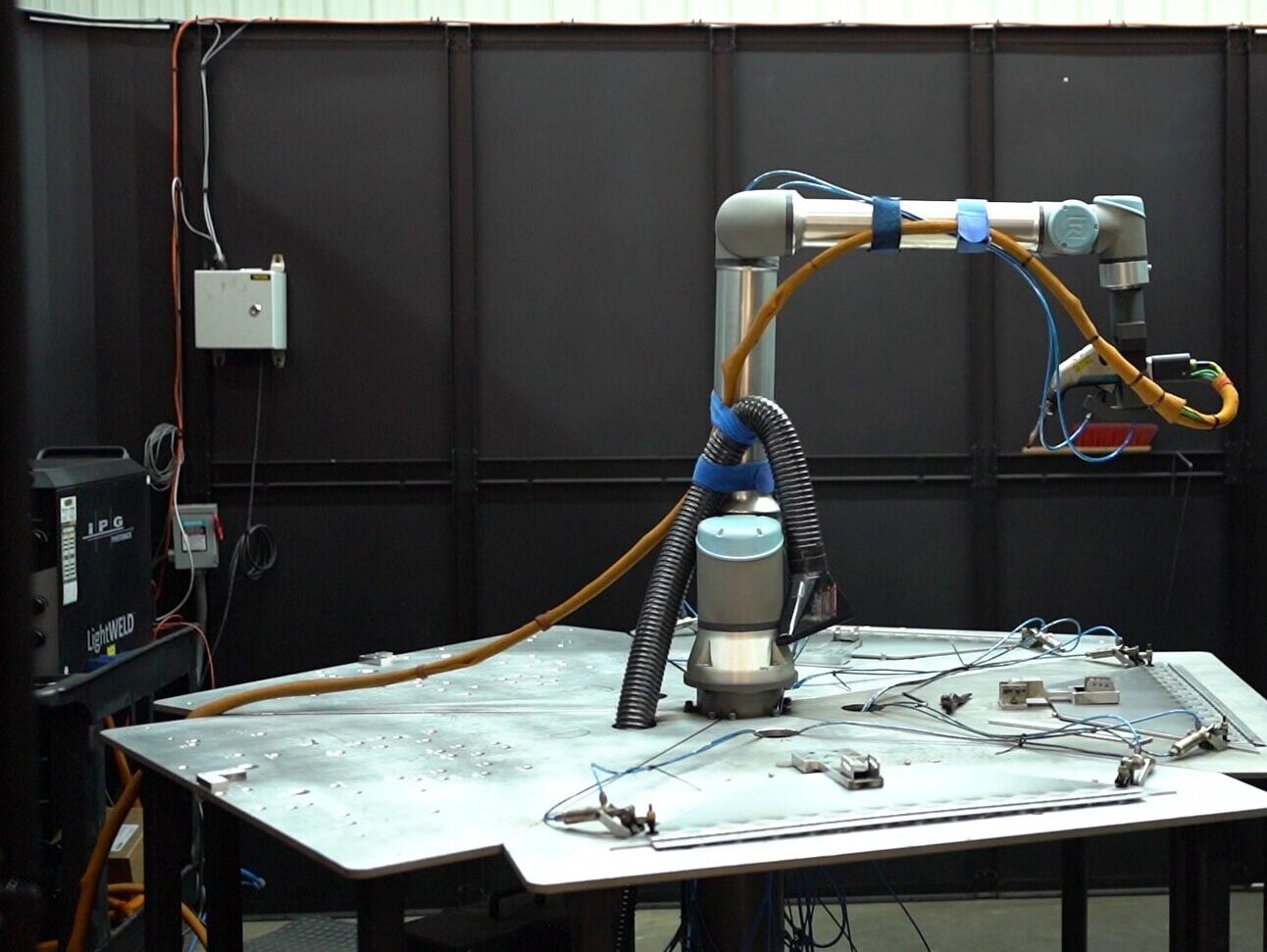

- Universal Robot UR10e cobot

IPG LightWeld laser welder & utilities dress package - UR Cap software & safety interface

- Workcell enclosure & access doors

- Work table & modular workholding fixtures & clamps

Increase Productivity and Flexibility with Superior-Quality Welds—Without Burdening Your Welders!

Take Advantage of an All-in-one Laser Welding Robot

Our comprehensive solution includes a UR10e cobot, IPG LightWeld laser welder, UR Cap software, safety interface, work cell enclosure, work table, and modular fixtures and clamps. The cobot system can weld a wide range of materials and material gauges, ensuring high-quality, repeatable results on every job.

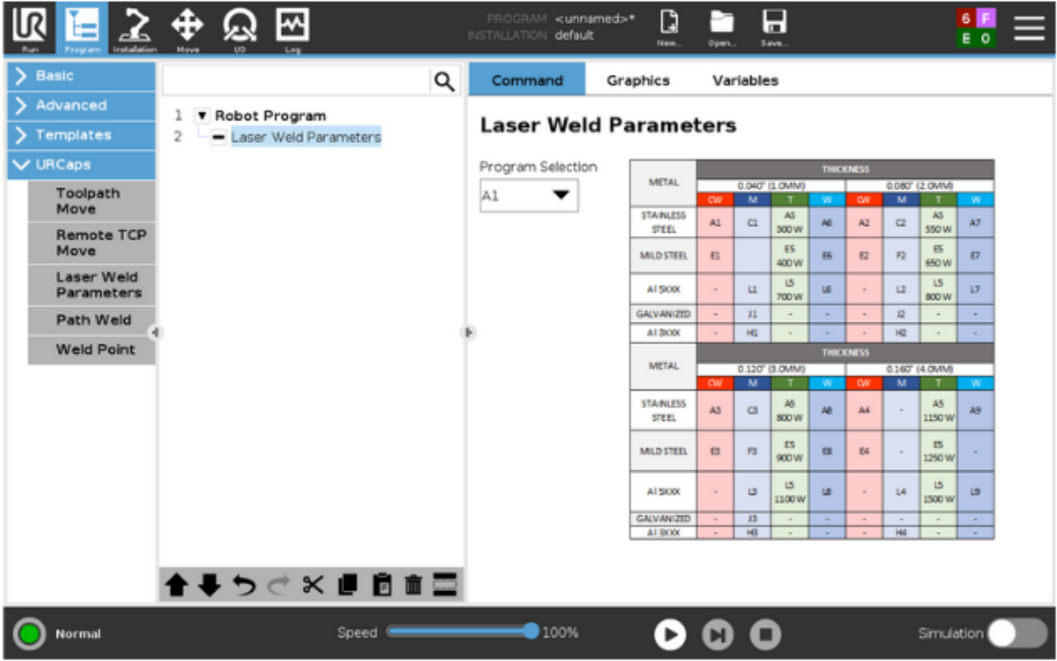

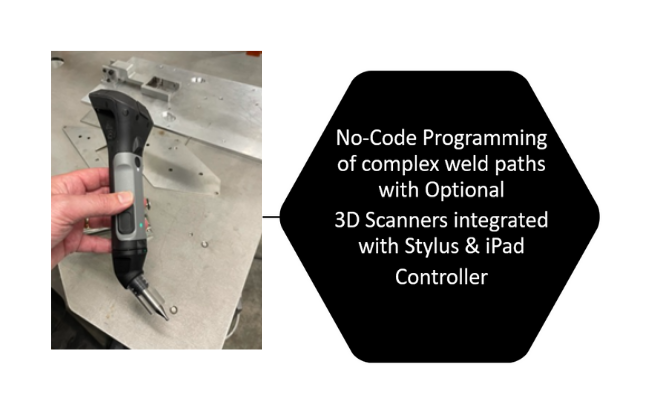

No Code Programming—Perfect for Your Actual Welders

The UR Cap Software, included with the Cobot, offers unparalleled ease of use. All laser welding parameters are selected with perfect reliability by the Cobot, ensuring the utmost efficiency.

The touchscreen display and intuitive user interface minimize the learning curve for all your employees, allowing your company to instantly put the Cobot to productive use. With NO CODE PROGRAMMING, the Cobot Laser Welding Package allows you to automate your small batch production with exceptional ease and affordably.

Why Automate Laser Welding?

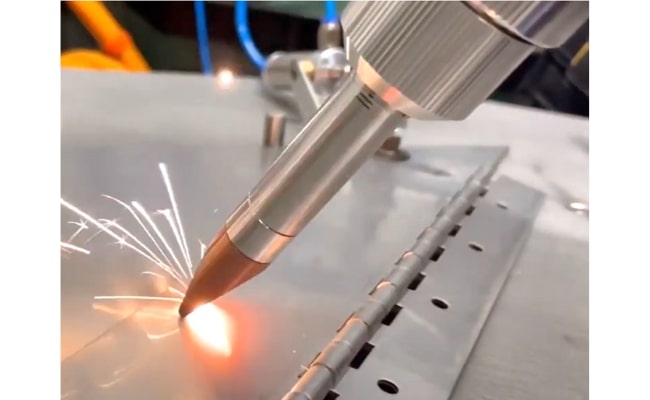

Laser Welding Is Fast, But It Can Be Faster and More Precise with a Cobot.

- Even if you have the manpower, manual welding processes can present quality and productivity challenges

- TIG welding is a difficult welding process to automate due to external wire feeding. Laser welding presents a solution that is easier to automate and up to 4X faster with great penetration and less distortion.

- Handheld laser welding can help manufacturers speed up their welding operations, however, these welds require a strong and steady grip.

Reach the full potential of laser welding by combining collaborative robotics to create a repeatable, fast and efficient production.

Gain Peace of Mind with Cutting Edge Machining & Automation Customer Care Program

We’re not simply robotics system suppliers. We will help you seamlessly integrate your laser welding robot into your operations—and help you optimize its use in production. Our Customer Care Program offers unmatched consulting, troubleshooting, and technical support to facilitate the transition to automation.

FAQs

What is a laser welding robot?

A laser welding robot is an automated system that uses a robotic arm with a laser welder tool. A laser welding robot is designed to achieve high precision and consistency in welding tasks, which makes it ideal for jobs requiring high quality and accuracy. Many industries, including automotive, aerospace, electronics, and medical device manufacturing, use laser welding robots to mitigate the drastic shortage of welders in the job market.

Is laser welding stronger than MIG?

Laser welding is oftentimes stronger than MIG—and at least three times faster—in many welding applications. You can use a laser welding robot to weld thin and thick joints, and it doesn’t require multiple passes or high temperatures.

Is laser welding worth it?

Yes! If you require high precision, high-quality welds, especially for complex or detailed tasks, laser welding is worth the investment. A laser welding robot is also very efficient for high-volume production, as it can be faster and produce less waste than traditional welding methods.

How much does a welding cobot cost?

The cost of a welding cobot can vary greatly depending on its capabilities, size, and the specific manufacturer. You can factor in $120k to $150k for a welding cobot package. For a more exact estimate of the cost of your operation, contact Cobot Systems to schedule an in-depth consultation.

We get it. The Welder Shortage Struggle Is Real.

But the struggle stops here. Cobot Systems laser welding robot is the key to scaling production without relying on a lengthy and often futile welding recruitment process.

Rest easy knowing your laser welding cobot system will safeguard your competitive edge and equip your welding team with advanced skills to help them perform better. Find out how.